1×7 Stainless Steel Wire Rope Product Introduction Overview: The 1×7 stainless steel wire rope is a high-quality, durable, and versatile wire rope constructed from a single strand of seven individual ...

See DetailsIn modern industry, transportation, construction, marine engineering and other fields, Steel Wire Rope is known as an invisible hero. Its strong load-bearing capacity and durability make it the core component of many high-strength traction, lifting and fixing systems.

1. What is Steel Wire Rope? Core analysis from structure to performance

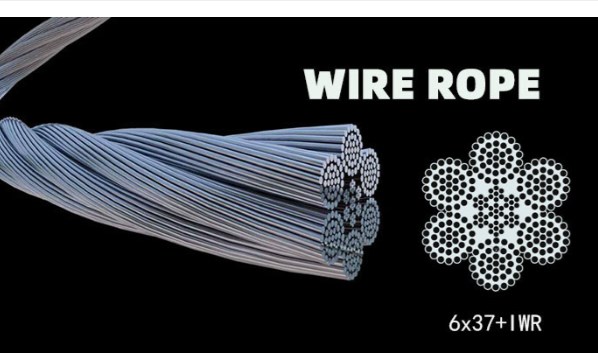

Steel wire rope is made of multiple high-strength steel wires twisted in a certain way, usually consisting of three parts: steel wire, rope core and lubricant. Its core advantages are strong load-bearing capacity, good flexibility, excellent fatigue resistance, and suitable for a variety of complex working conditions.

Common structural forms include:

6×19 wire rope: composed of 6 strands, 19 strands per strand, high softness, suitable for lifting equipment;

6×37 wire rope: single strand is thinner, more flexible, used in places requiring high bending performance;

8-strand wire rope: strong anti-rotation performance, widely used in high-altitude hoisting;

Rotary wire rope: specially designed structure prevents spinning during hoisting to ensure operation safety.

Depending on the purpose and needs, different rope core materials will also be selected, such as hemp core, steel core, plastic core, etc. Among them, the steel core enhances the compressive strength, while the plastic core improves the lubricity and corrosion resistance.

2. Steel Wire Rope Classification Review: Meeting the Needs of Various Working Conditions

In order to meet the needs of different industrial scenarios, steel wire ropes are constantly evolving in terms of materials and structures. The main classifications include:

1. Classification by use:

Lifting steel wire ropes: such as tower cranes, elevators, and bridge cranes, requiring high breaking tension and fatigue resistance;

Mining steel wire ropes: used for underground lifting and traction, requiring extremely high wear resistance and corrosion resistance;

Power line traction steel wire ropes: used for laying power transmission lines, often using galvanized steel wire ropes with strong anti-oxidation properties;

Marine engineering steel wire ropes: long-term operation in seawater environments, requiring resistance to salt spray corrosion;

Aviation or military steel wire ropes: have extremely high requirements for accuracy, weight, and fatigue life, and usually use special alloy steel wires.

2. Classification by surface treatment:

Smooth steel wire rope: no surface treatment, suitable for indoor or short-term working conditions;

Galvanized steel wire rope: common anti-rust treatment, suitable for outdoor and humid environments;

Stainless steel wire rope: suitable for strong corrosion or high hygiene requirements, such as food machinery, medical equipment, etc.;

Plastic-coated steel wire rope: polyethylene or polyurethane is wrapped on the surface of the steel wire, which has multiple properties such as insulation, wear resistance and corrosion resistance.

3. How to choose a suitable Steel Wire Rope? Four major factors cannot be ignored

When selecting, not only pay attention to the price, but also need to consider the following core factors comprehensively:

1. Carrying capacity and safety factor

Ensure that the breaking tension of the steel wire rope is much higher than the actual use load. Generally, the safety factor is recommended to be between 5 and 8.

2. Use environment

Is it a high-humidity, high-corrosion, high-frequency bending scene? If so, it is recommended to choose galvanized or stainless steel wire rope.

3. Fatigue resistance

If the steel wire rope needs to be frequently hoisted and repeatedly bent, it is recommended to choose a steel wire rope with thin steel wire and multi-strand structure.

4. Rotation control

For operations that require precise positioning, such as high-altitude lifting, anti-rotation wire ropes must be used to avoid accidents caused by the self-rotation of the rope during the lifting process.

IV. Maintenance and scrapping standards of wire ropes: the key to ensuring safe operation

As a high-strength consumable, daily maintenance of wire ropes is essential. The following are the main precautions:

Lubrication and maintenance: Regularly apply professional wire rope grease to reduce friction between wires;

Regular inspection: Check for broken wires, rust, deformation, bending, etc.;

Meet the scrapping standard: If the number of broken wires in a rope pitch exceeds the specified value (such as 6×19 structure must not exceed 30%), it must be replaced immediately.

Steel Wire Rope plays a vital role in large-scale projects, safe operations, and equipment operation. In-depth understanding of its structure, accurate selection of different scenarios, and rigorous maintenance during use are the basis for ensuring efficient, safe, and long-term operation of industrial systems. With the integration of technology iteration and intelligence, wire ropes are gradually transforming from "hardware products" to "intelligent equipment", and the future is promising.