1×7 Stainless Steel Wire Rope Product Introduction Overview: The 1×7 stainless steel wire rope is a high-quality, durable, and versatile wire rope constructed from a single strand of seven individual ...

See DetailsIn the global industrial chain, there is a core material that seems inconspicuous but is related to the safety of major projects - wire rope. From suspension bridges across rivers to mining deep underground, from 10,000-ton cranes to deep-sea exploration equipment, China Steel Wire Rope has gradually become the "hidden champion" in the global market with its excellent performance and cost-effectiveness. Today, China is not only the world's largest producer of wire ropes, but also has achieved a leap from "following" to "leading" in the high-end field, writing a legend of China's counterattack.

Hundred years of process iteration: from "shoddy" to "millimeter-level precision"

The history of wire rope can be traced back to the 19th century, and the China Steel Wire Rope industry started in the 1950s. In the early days, due to the limitations of technical equipment and material processes, domestic wire ropes generally had problems such as low strength, poor toughness, and short life, and the high-end market was long monopolized by European and Japanese companies. At that time, major domestic projects such as bridge construction and large lifting equipment had to rely on imported products, which were not only costly but also often faced the risk of unstable supply cycles.

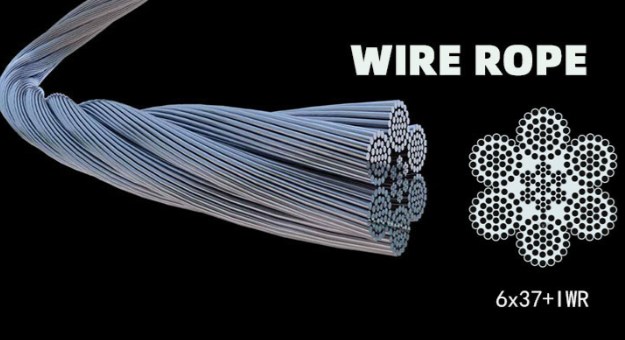

The turning point began with the introduction of technology and independent research and development after the reform and opening up. By digesting and absorbing the advanced twisting technology of Germany and Japan, Chinese companies have gradually mastered core processes such as "multi-layer strands without rotation" and "compacted strands". Entering the 21st century, with the breakthrough of localization of high-strength steel wire materials (such as 82B and 87MnA), the breaking force of wire ropes has increased by more than 30%, and the fatigue life has been extended to 2-3 times that of traditional products. Today, leading domestic companies can produce a full range of products with diameters ranging from 0.15 mm to 360 mm, with an accuracy control of ±0.01 mm, meeting the diverse needs from precision instruments to super-large projects.

Application scenario breaking the wall: from "infrastructure rigid needs" to "deep sea and deep space"

In the field of infrastructure construction, China Steel Wire Rope has long become a "standard configuration". The Hong Kong-Zhuhai-Macao Bridge's cable-stayed cables use high-strength galvanized aluminum alloy steel wire ropes with a diameter of 7 mm. Each steel wire can withstand a tensile force of 12 tons, and the entire cable can bear a load of up to 5,000 tons, which can maintain structural stability in a strong typhoon environment; during the construction of the Shanghai Tower, special anti-rotation steel wire ropes were used to hoist 600 tons of steel structure components, with an error control of less than 5 mm, setting a world record for the hoisting accuracy of super-high-rise buildings.

Even more remarkable is the breakthrough in high-end fields. In the field of deep-sea exploration, the umbilical cable steel wire rope used in China's independently developed "Jiaolong" manned submersible can withstand high pressure at a depth of 7,000 meters, and has the characteristics of corrosion resistance and wear resistance, breaking the technical blockade of foreign companies; in the field of aerospace, the traction system of the rocket launch tower uses lightweight high-strength steel wire ropes, which are 40% lighter than traditional products, but can withstand the huge impact of the rocket taking off. The expansion of these application scenarios not only reflects the technical strength of China Steel Wire Rope, but also highlights its supporting role in the country's major strategies.

Future technical direction: dual revolution of greening and intelligence

The China Steel Wire Rope industry is ushering in new changes. In terms of greening, environmentally friendly processes such as lead-free plating and water-based anti-corrosion coatings gradually replace traditional galvanizing processes, reducing harmful substance emissions by more than 60%; through material recycling technology, the recycling rate of waste steel wire ropes reaches 95%, forming a "production-use-recycling" circular economy model.

From bridge cables to deep-sea cables, from factory cranes to aerospace launch pads, every technological breakthrough of China Steel Wire Rope is reshaping the industry landscape. It is not only the "bones and muscles" of the industrial field, but also a microcosm of China's manufacturing transformation and upgrading. In the future global competition, with the continuous emergence of new materials and new processes, China Steel Wire Rope will surely write a new chapter of "China's Intelligent Manufacturing" with higher quality and broader application scenarios.