1×7 Stainless Steel Wire Rope Product Introduction Overview: The 1×7 stainless steel wire rope is a high-quality, durable, and versatile wire rope constructed from a single strand of seven individual ...

See DetailsSteel wire rope, as one of the indispensable core materials in modern industry, is widely used in various fields including construction, ports, mining, and lifting and transportation. China Steel Wire Rope, with its excellent manufacturing process, stable product performance, and high cost-effectiveness, has gradually become a focus of attention in the global market.

The performance of steel wire rope is critically dependent on the steel used. China Steel Wire Rope typically uses high-carbon steel or alloy steel, processed through rigorous smelting and precise drawing processes, ensuring that the steel wire itself possesses excellent strength and wear resistance. High-carbon steel provides basic tensile strength, while alloy steel excels in fatigue resistance and corrosion resistance. The choice of different steel materials directly affects the service life and safety factor of the steel wire rope.

During processing, the steel wire undergoes multiple cold drawing and heat treatment processes to ensure a dense and uniform internal structure. This process not only improves the tensile strength of the steel wire but also enhances its wear resistance and fatigue resistance. China Steel Wire Rope manufacturers usually strictly control the diameter tolerance and surface finish of each steel wire to ensure that after being wound into a rope, the individual wires fit together tightly, forming a stable rope core structure.

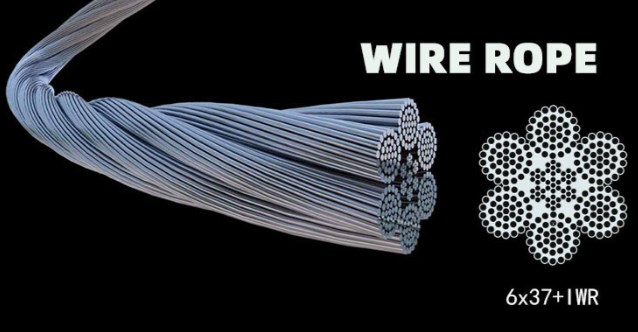

The performance of China Steel Wire Rope depends not only on the steel material but also on its rope core structure. Steel wire rope is usually composed of multiple strands of steel wire wound together according to a certain pattern, and then multiple strands are combined to form the entire steel wire rope. The rope core can be divided into fiber core (FC), steel wire core (IWRC), and composite core, each with its unique performance advantages.

Fiber cores offer better flexibility, providing a certain cushioning and lubrication effect, suitable for applications requiring flexible operation. Steel wire cores have high rigidity and strong load-bearing capacity, suitable for high-load operations. Composite cores combine the characteristics of both, maintaining load-bearing capacity while improving flexibility. The precision of these structural designs directly affects the compressive strength, tensile strength, and wear resistance of the steel wire rope, and is a core factor in enabling China Steel Wire Rope to maintain stable performance in engineering applications.

In practical use, steel wire ropes often face challenges from friction, weathering, and chemical corrosion. China Steel Wire Rope significantly enhances its durability and environmental adaptability through various surface treatment technologies. Galvanizing is the most common process, forming a protective layer on the steel wire surface to effectively resist corrosion caused by humidity and salt spray. For high-strength and special environmental requirements, stainless steel materials or coatings can be used to further improve oxidation resistance and wear resistance.

At the same time, the quality of surface treatment directly affects the service life of the steel wire rope. A uniform coating not only prevents localized corrosion but also reduces wear caused by friction between strands. China Steel Wire Rope manufacturers usually conduct rigorous surface inspections during the production process to ensure that each wire maintains high performance during long-term use.

During lifting, traction, and hoisting operations, steel wire ropes need to withstand frequent stretching, bending, and repeated loads. China Steel Wire Rope optimizes the wire arrangement, strand structure, and core design to provide excellent tensile strength and fatigue life. The performance stability of the steel wire rope is particularly important under continuous bending or high-load conditions. The balanced stress distribution design between strands effectively disperses stress, reduces the risk of localized fatigue damage, and thus ensures the overall structural safety and reliability.

The elasticity and flexibility of the steel wire rope also affect ease of operation and service life. China Steel Wire Rope adjusts the number of strands, wire diameter, and winding method according to different application scenarios to achieve the best balance between flexibility and strength. This refined design allows the steel wire rope to maintain long-term stable performance in high-intensity use environments.

Due to its excellent mechanical properties and diverse structures, China Steel Wire Rope is widely used in various industrial fields. In scenarios such as port lifting, mining transportation, and construction hoisting, steel wire ropes need to meet multiple requirements simultaneously, including high strength, wear resistance, and corrosion resistance. By rationally selecting the core type, number of strands, and surface treatment method, China Steel Wire Rope can provide customized solutions for different applications, achieving a balance between performance optimization and cost control.

In complex environments such as high temperatures, low temperatures, or humid marine conditions, the corrosion resistance and fatigue resistance of steel wire ropes are particularly important. China Steel Wire Rope, through high-standard manufacturing processes and material selection, maintains stable and reliable performance under various harsh conditions, ensuring equipment safety and production efficiency.

High-performance China Steel Wire Rope relies on rigorous quality testing. Manufacturers typically conduct comprehensive testing on wire strength, strand structure, surface treatment thickness, tensile strength, and fatigue life. Standardized production processes ensure the dimensional accuracy and performance consistency of each steel wire rope, thereby reducing the risk of failure under high-load use.

In international and domestic markets, China Steel Wire Rope typically adheres to standards such as ISO, DIN, or GB. These standards not only regulate the structure, performance indicators, and testing methods of steel wire ropes but also provide reliable quality assurance for customers.

A1: The main difference lies in the manufacturing process and quality control. China Steel Wire Rope typically uses high-precision cold-drawn steel wire, multi-strand structure design, and strict surface treatment, making it superior in strength, wear resistance, and fatigue resistance.

A2: Fiber cores are suitable for operating environments requiring high flexibility, steel wire cores are suitable for scenarios requiring high load-bearing capacity, and composite cores combine both strength and flexibility. The choice should be determined based on load requirements and operating environment.

A3: Surface treatment directly affects the corrosion resistance and wear resistance of the steel wire rope. A uniform plating or coating can significantly extend the service life, especially in humid or marine environments.

A4: It is widely used in port lifting, mining transportation, construction hoisting, cableway traction, and other scenarios, especially suitable for working environments requiring high strength and high durability.

A5: Regularly checking for strand wear and corrosion, maintaining lubrication, and avoiding overloading and frequent bending can effectively extend the service life of China Steel Wire Rope.