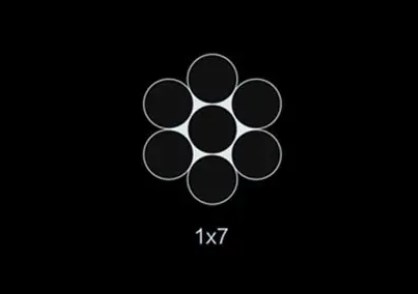

1×7 Stainless Steel Wire Rope Product Introduction Overview: The 1×7 stainless steel wire rope is a high-quality, durable, and versatile wire rope constructed from a single strand of seven individual ...

See DetailsAs an important industrial material, stainless steel wire rope is widely used in construction, navigation, aviation, bridge construction and mining. Its strength, corrosion resistance and tensile strength make it an indispensable element in many industries.

Basic characteristics of stainless steel wire rope

Stainless steel wire rope is woven from multiple strands of stainless steel wire according to a certain structure. Compared with ordinary wire rope, stainless steel wire rope has the following outstanding characteristics:

Corrosion resistance: One of the biggest advantages of stainless steel wire rope is its excellent corrosion resistance. In humid, salt spray, chemicals and high temperature environments, it can still maintain good performance, avoiding the breakage or performance degradation of traditional wire ropes due to corrosion.

High strength and high wear resistance: Stainless steel wire rope has high tensile strength, can withstand greater loads, and is not easy to wear during long-term use, extending its service life.

High temperature resistance: Stainless steel wire rope has strong high temperature resistance, can maintain high mechanical strength at high temperatures, and is suitable for high temperature working environments.

Toughness and flexibility: Stainless steel wire rope has good toughness, can maintain high elasticity and strength under large deformation, and has certain impact resistance.

Manufacturing process of stainless steel wire rope

The manufacturing process of stainless steel wire rope is relatively complicated, usually including the following main steps:

Material selection: When making stainless steel wire rope, you first need to select suitable raw materials. Commonly used stainless steel materials include 304, 316, etc., which have excellent corrosion resistance and strength.

Wire drawing process: Wire drawing is to draw large-diameter metal materials into smaller-diameter steel wires through a die. This process not only improves the strength of the metal, but also ensures a smooth surface of the steel wire.

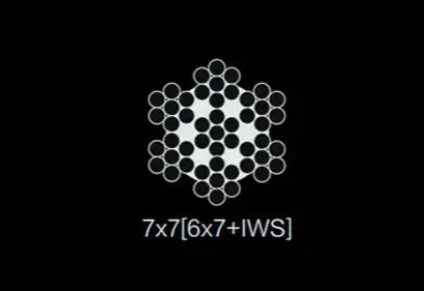

Braiding and twisting: After the wire drawing process, the steel wire enters the braiding or twisting stage. The steel wire is braided according to the required specifications and applications to form a certain number of strands and twist. The choice of braiding structure will directly affect the strength and service life of the wire rope.

Heat treatment and surface treatment: In order to improve the corrosion resistance and wear resistance of the steel wire, heat treatment and surface treatment are usually performed during the production process. Common surface treatment methods include polishing, nickel plating and galvanizing, which can further improve the performance of wire ropes.

Main applications of stainless steel wire ropes

Stainless steel wire ropes are widely used in many industries due to their superior performance.

Construction engineering: Stainless steel wire ropes are often used in the hoisting, lifting, cable and other structures of high-rise buildings, with the advantages of strong bearing capacity, good stability and strong weather resistance.

Navigation and aviation: In the fields of navigation and aviation, stainless steel wire ropes are mainly used for anchor chains, cables and aircraft towing ropes of ships, which can withstand high loads and are not easy to rust.

Bridge construction: In the construction of modern bridges, stainless steel wire ropes are widely used for the connection and support of bridge deck cables, which can effectively improve the overall structural stability of bridges.

Mining and energy fields: In mining and energy industries, stainless steel wire ropes are used for lifting and transporting ore, etc., and can withstand the working load in high temperature and corrosive environments.

Mechanical equipment and lifting equipment: In equipment such as cranes and lifts, stainless steel wire ropes also play an important role, providing strong bearing capacity and safety guarantees.

Analysis of the advantages of stainless steel wire ropes

The advantages of stainless steel wire ropes during use are not only reflected in their superior physical properties, but also in their low maintenance costs and long service life.

Extended service life: Since stainless steel wire ropes have strong corrosion resistance, they have a long service life even in harsh working environments, reducing the cost of frequent replacement.

Reduced maintenance costs: The wear resistance of stainless steel wire ropes makes them less damaged during use, reducing the frequency of maintenance and replacement, thereby greatly reducing maintenance costs.

High safety: Stainless steel wire ropes can not only withstand high loads, but also have good impact resistance, making them much safer than ordinary wire ropes in critical applications.

Good environmental protection: Stainless steel wire ropes have strong corrosion resistance and anti-pollution capabilities, can reduce environmental pollution, and meet current environmental protection requirements.

Future development trends

With the continuous advancement of technology, the application and performance of stainless steel wire ropes are also constantly improving.

Research and development of new materials: Researchers are working on the development of new stainless steel alloy materials to further improve the high temperature resistance, corrosion resistance, wear resistance and other properties of wire ropes.

Intelligent monitoring: With the development of intelligent technology, the application of stainless steel wire ropes in the future may be combined with sensors and monitoring systems to achieve real-time monitoring of the working status of wire ropes and early warning of potential failures.

Green and environmental protection: Environmental protection requirements are becoming more and more stringent. In the future, the production process of stainless steel wire ropes will be more environmentally friendly, using less energy and resources, and reducing waste emissions.