Stainless steel bolts are a common type of fastener widely used across various industries. Due to their excellent corrosion resistance and strength, stainless steel bolts have become indispensable components in industrie...

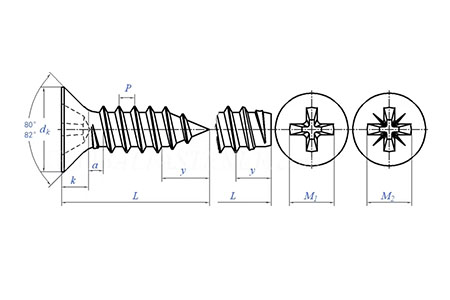

READ MORECross Countersunk Head Self-tapping Screw is a commonly used fastener, the design concept combines self-tapping function with countersunk head shape, which is widely used in construction, furniture making and home DIY.

The head of the screw has a Phillips slot shape, which can be used with a standard Phillips screwdriver, improving the grip during operation and avoiding slippage.

The use of countersunk head design allows the screw to be completely recessed into the surface of the material after installation, ensuring that the connection point is neat and beautiful, and reducing scratches or injuries caused by exposed head.

The special thread design of self-tapping screws enables them to be drilled directly into materials (e.g. wood, plastic, thin metal, etc.) without the need for pre-punched holes, which greatly saves installation time and labor costs.

Usually made of carbon steel, stainless steel or alloy steel, with good durability and corrosion resistance, suitable for different use environments.

Application Areas:

Furniture manufacturing: suitable for the assembly of wooden furniture to ensure a strong and aesthetically pleasing connection.

Construction: Widely used in the fixing of walls, floors and other structures to enhance the stability of the components.

Home decoration: can be used to install panels, ceilings and various decorative materials, to ensure a smooth surface.

Electronics: Used for fixing electronic equipment housings and internal components, providing a solid connection.

| Thread Size | ST2.2 | ST2.9 | ST3.5 | (ST3.9) | ST4.2 | ST4.8 | ST5.5 | ST6.3 | |

| P | Pitch | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 |

| a | max | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 |

| dk | max=nominal size | 4.3 | 5.5 | 6.8 | 7.5 | 8.1 | 9.5 | 10.8 | 12.4 |

| min | 4 | 5.2 | 6.44 | 7.14 | 7.74 | 9.14 | 10.37 | 11.97 | |

| k | 1.3 | 1.7 | 2.1 | 2.3 | 2.5 | 3 | 3.4 | 3.8 | |

| y | TypeC | 2 | 2.6 | 3.2 | 3.5 | 3.7 | 4.3 | 5 | 6 |

| max Type F | 1.6 | 2.1 | 2.5 | 2.7 | 2.8 | 3.2 | 3.6 | 3.6 | |

| Socket No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | |

| M₁ | ≈ | 2.5 | 3 | 4.2 | 4.6 | 4.7 | 5.1 | 6.8 | 7.1 |

| M2 | ≈ | 2.4 | 2.8 | 4 | 4.2 | 4.4 | 5 | 6.3 | 7 |

Stainless steel bolts are a common type of fastener widely used across various industries. Due to their excellent corrosion resistance and strength, stainless steel bolts have become indispensable components in industrie...

READ MOREStainless steel wire rope is a high-strength material widely used in various industrial fields. With its excellent corrosion resistance, outstanding mechanical strength, and superior fatigue resistance, it has become an ...

READ MOREIn modern shipbuilding and maintenance, marine hardware plays an irreplaceable role. From small recreational boats to large commercial vessels, the safety, durability, and operational convenience of ships all depend on h...

READ MORE